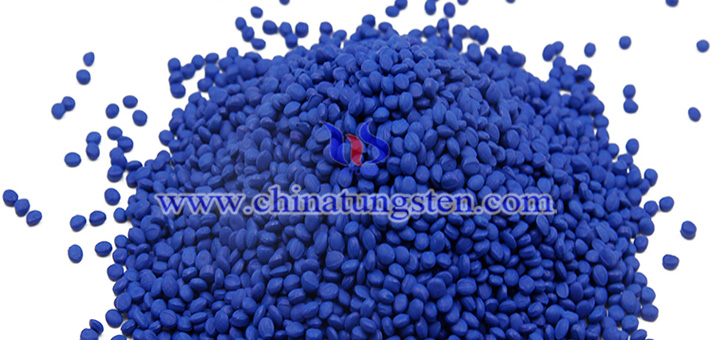

Nanometer blue tungsten oxide for thermal insulation masterbatch can be prepared by a self-reduction process of ammonium paratungstate. In other words, by adjusting other process parameters without inletting hydrogen or NH3, the blue tungsten oxide can be prepared stably. Observing the effect of temperature on blue tungsten oxide, it was found that:

With the increase of temperature, the particle size of blue tungsten oxide changed irregularly. But, the change was small. It proved that the temperature condition was not significant in the range of test temperature (600~800°C). While the oxygen index (O/W) showed a downward trend. And the residual ammonia also showed a downward trend. This was because, in the process of micro-reduction of ammonium paratungstate at high temperature, the degree of removal of crystallization water and ammonia by ammonium paratungstate was intensified with the increase of temperature. And the process of NH3 pyrolysis at high temperature to produce hydrogen was also intensified. In other words, the hydrogen atmosphere was increased, and the degree of reduction of hydrogen to ammonium paratungstate was enhanced. Therefore, the oxygen index decreased with the increasing of temperature. In addition, the particle size alone was not significantly affected by the change of temperature. And the oxygen index and residual ammonia decreased with increasing temperature.

More details, please visit:

http://www.tungsten-powder.com/Blue-Tungsten-Oxide.html