How to choose tungsten carbide thread milling cutter? Tungsten carbide thread milling cutters have two main types: single-row thread milling cutters and multi-row thread milling cutters. And there are different shanks including hydraulic shanks, spring shanks and hot tension shanks.

More details, please visit:

http://www.tungsten-carbide.com.cn/tungsten-carbide-blade-bar.html

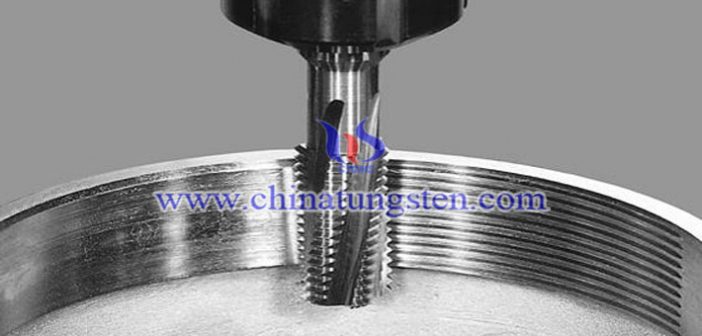

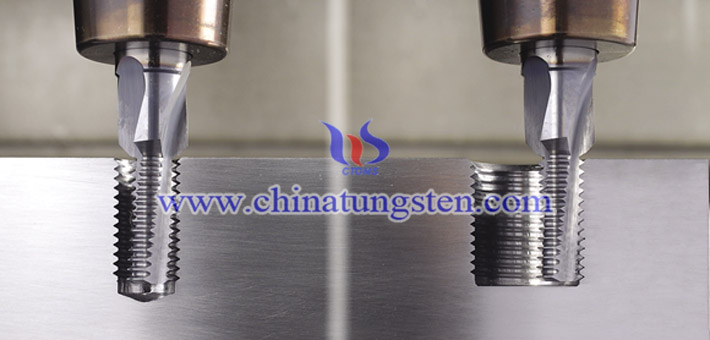

Firstly, take their applications in to account. The two types of tungsten carbide thread milling cutters have different applications. Tungsten carbide single-row thread milling cutter is used to process medium to large internal threads, or large external threads on asymmetric parts. And it is also applied for places where require low power, or have poor stability, or need to process many different pitches with the same blade. Tungsten carbide multi-row thread milling cutter is used to process the thread and chamfer at the same time with one tool, to process the complete thread length with a single 360° spiral pass, and to process threads of multiple sizes (same pitch) with the same tool.

Secondly, choose shank with ideal runout accuracy to extend tool life.