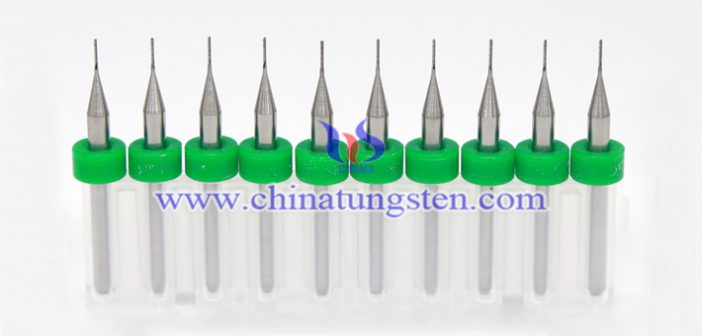

Tungsten carbide milling cutter is made of ultrafine grain cemented carbide material that has properties of high hardness, sufficient bending strength and excellent wear resistance and has good milling and cutting performance to ensure high work efficiency. Also, the slots, holes and edges are clean, tidy, and free of burrs. Tungsten carbide milling cutters are mainly used in PCB (Printed Circuit Board) processing, so it is also called tungsten carbide PCB milling cutters.

More details, please visit:

http://www.tungsten-carbide.com.cn/tungsten-carbide-blade-bar.html

Tungsten Carbide Milling Cutter Maintenance

1. Check the power and stiffness of the machine tool to ensure that the required diameter of milling cutter can be matched with the machine tool.

2. The overhang of milling cutter on the spindle is as short as possible to reduce the impact of the milling cutter axis and workpiece position on the impact load.

3. Use correct cutter pitch suitable for the process to ensure that there are not too many blades engaging with the workpiece at the same time to cause vibration while cutting. On the other hand, when milling a narrow workpiece or a cavity, make sure that there is enough blade to engage the workpiece.

4. Select correct feed rate and tool cutting edge angle. Use cutting fluid duly.