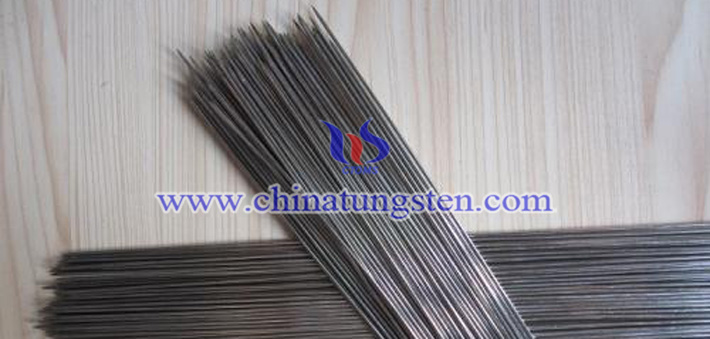

Tungsten pin may be prepared by electrolytic process using thin tungsten wire as raw material, which has advantages of high hardness, good rust resistance and strong ductility. And the pin made of tungsten is not easy to break so that it is durable with long service life. What is more, it can be reused after electrolysis if there is wear or tear.

Tungsten Pin Prepared by Electrolysis

1. Experimental material:

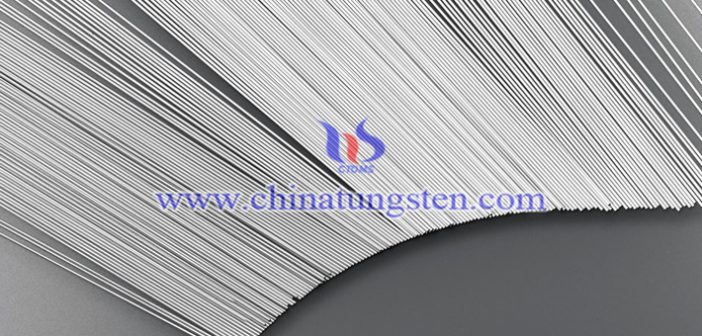

(1) Thin tungsten wire, diameter of 0.32mm, length about 5cm.

(2) Power: No.1 battery, 2 sections.

(3) Electrolyte: Dissolve 100g potassium hydroxide in 100ml distilled water to make into 13K KOH solution and store it in a glass beaker.

2. Experimental procedures:

Put the tip of the anode (tungsten pin) and the cathode (carbon rod) in the electrolyte, which means the circuit was turned on. Immediately, a large number of air bubbles overflowed from the carbon rod. And the tungsten wire showed chipping off, indicating that the electrolysis was proceeding. The electrolysis time is about 1min. During the electrolysis process, the depth of the tungsten tip immersed in the electrolyte can be changed at any time to adjust the sharpness of the tip.

More details, please visit:

http://www.tungsten.com.cn/tungsten-pin.html