There are four types of resistance welding, which can use tungsten copper bonded copper electrode as welding tip, spot welding, seam welding, butt welding and projection welding.

Spot welding assembles the weldment into a lap joint and presses it between two cylindrical electrodes to melt the base metal using resistance heat to form a solder joint, which is mainly used for thin plate welding. The processes are preloading to ensure good contact of the workpiece, energizing to form nugget and plastic ring at the weld, power-off forging, so that the nugget cools and crystallizes under the continued pressure to form a densely structured solder joint without shrinkage or cracks.

The process of seam welding is similar to spot welding, except that the cylindrical electrode is replaced by a rotating disc-shaped roller electrode, and the weldment is assembled into a lap or butt joint and placed between the two roller electrodes. The roller pressure welding is a welding process in which the parts are rotated, continuously or intermittently, to form a continuous weld. Seam welding is mainly used for welding structures with relatively regular weld seams and sealing requirements. The plate thickness is generally below 3mm.

Butt welding welds the weldment along the entire contact surface.

1.0 Resistance butt welding

Resistance butt welding is a method of assembling the weldment into a butt joint so that its end faces are in close contact, using resistance heat to heat it to a plastic state, then the power is cut off and the upsetting force is quickly applied to complete the welding.

Resistance butt welding is mainly used for weldments with a simple cross-section, a diameter or side length of less than 20mm and a low strength requirement.

2.0 Flash butt welding

Flash butt welding is to assemble the weldment into a butt joint, turn on the power, and make the end face gradually move closer to reach local contact, and use resistance heat to heat these contact points. Under the action of large current, flash is generated to melt the end face metal until the end when the part reaches a predetermined temperature within a certain depth range, the power is turned off and the upsetting force is quickly applied to complete the welding.

The joint quality of flash welding is better, and the mechanical properties of the weld are equivalent to the base metal, and there is no need to clean the pre-welded surface of the joint before welding. Flash butt welding is often used for welding important weldments. It can weld the same kind of metal, also can weld dissimilar metals; it can weld 0.01mm metal wire, and also can weld 20,000mm metal rod and profile.

Projection welding is a variant of spot welding, there are prefabricated bumps on a workpiece, and one or more nuggets can be formed at the joint at a time. The quality of projection welding is determined by current, power-on time, pressure, and diameter of the resistor tip.

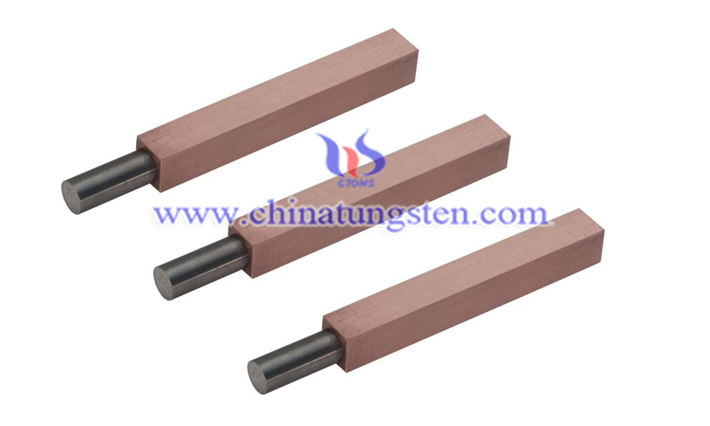

Whichever the resistance welding method is chosen, copper tungsten electrode is a necessary part. And it is used because of its high electricity conductivity. Besides, the shape can be customized as electrode, rod, round disk, round plate with hole, cup shape, etc. moreover, even though the regular contents are 70W30Cu and 80W20Cu, Chinatungsten can also make the parts with certain content as requirements by the clients for example decreasing the copper content to improve its to-be-cut property, and increasing the copper content to improve its electricity conductivity. No matter what kind of issues you are encountering, you are welcomed to be shared with and CTOMS will try to provide you a suitable solution and is eager to offer you samples based on the solution.