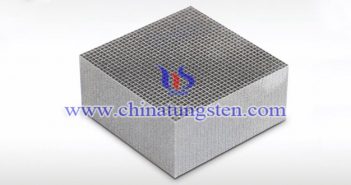

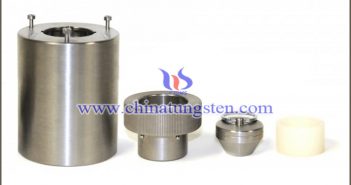

Military tungsten alloy cube refers to tungsten alloy cube manufactured by metal injection molding process for military use. It has good physical and chemical properties, such as high density, high hardness, good ductility, high temperature corrosion resistance, good compressive strength, oxidation resistance, electrical and thermal conductivity, non-toxic, non-polluting, etc., so that it is widely used as filling materials for armor-piercing projectile core or as counterweights. More details, please visit: http://www.tungsten-alloy.com/en/alloy04.htm Composition and specifications of military tungsten alloy cube are shown…