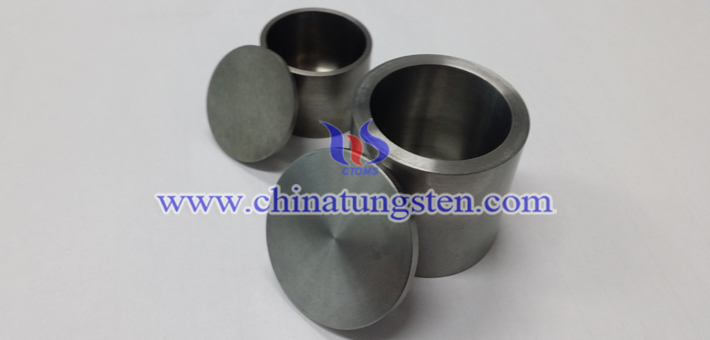

Sintering tungsten crucible means the tungsten crucible is produced by isostatic pressing – sintering, which is one of the most important preparation technologies for manufacturing tungsten crucibles today.

The isostatic pressing - sintering mainly includes processes such as powder mixing, powder loading, isostatic pressing, high temperature sintering, lathing, and finished product inspection.

There are some main factors for the cracking of tungsten crucibles - powder mixing, pressing pressure, and the angle of fillet at the bottom of the core, the heating rate and cooling rate during sintering process, and so on.

Producing Process of Sintering Tungsten Crucible

1. Assemble the mold according to the size of the finished product, fill tungsten powder that meets the requirements of national standard into the mold, sealing, and put it into a cold isostatic press to press it. The forming pressure is generally set at the range of 180~250 MPa.

2. The compact is placed in a high temperature induction sintering furnace for sintering. The heating rate is 80~150°C/h. The maximum temperature is 2200~2400°C. High temperature holding time is 4~8h.

3. Lathe the sintering compact in accordance with the requirements of finished product.

4. Quality inspection of the finished product, such as appearance, size, density, and so on.

More details, please visit:

http://www.tungsten.com.cn/tungsten-crucible.html