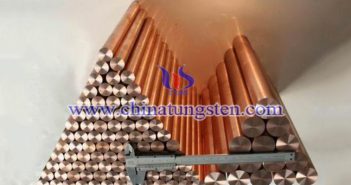

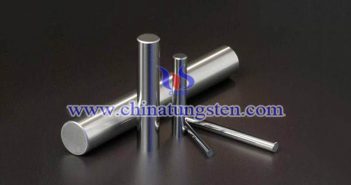

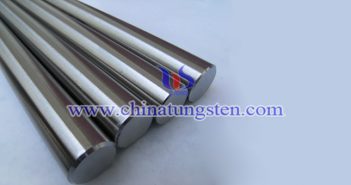

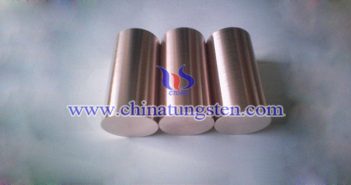

ATM1801 tungsten alloy rod has excellent radiation resistance, electric and thermal conductivities and corrosion resistance characters. It is extensively used in aerospace industry and is highly suitable for high heating applications such as welding. The properties of ATM1801 tungsten alloy rod are: Matrix: 95.0% W Binder: 5.0% Ni-Cu Density: 17.75~18.35 g/cm3 Tensile Strength: ≥648MPa Yield Strength (0.2% offset): ≥517MPa Modulus of Elasticity:≥1% Hardness Rockwell: 34C Magnetic Properties: Non-magnetic Chinatungsten Online can custom machine any tungsten alloy rod according to your…