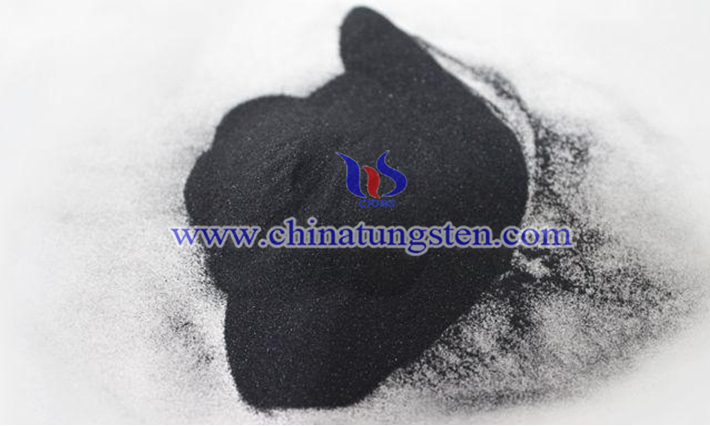

Ultrafine tungsten powder is the important raw material for producing fine grain cemented carbide, the raw materials for producing superfine tungsten powder consist purple tungsten oxide(purple tungsten) and blue tungsten oxide(blue tungsten). Blue tungsten oxide is most widely used raw material to produce tungsten powder by hydrogen reduction method. As long as the conditions are low temperature, dry hydrogen, high hydrogen flow and thin material layer, ultrafine tungsten powder is able to be produced by hydrogen reduction method. However, too high hydrogen flow and thin material layer will increase the cost. Purple tungsten oxide is a type of tungsten oxide product developed in recent years. It has unique properties and many advantages in the production of ultra-fine tungsten powder. Many metallurgical experts do wide range of research on it. Producing fine and uniform superfine tungsten powder is the key to producing superfine grain cemented carbide.

In the current production of ultra-fine tungsten powder, two kinds of raw materials are used at the same time, hydrogen reduction tests are made under the same technique conditions, then compare the difference of particle size and uniformity of reduced tungsten powder, so as to determine which kind of raw material is more suitable for the production of ultra-fine tungsten powder, the test shows the difference of particle size and uniformity of tungsten powder after reduction in two aspects:

In the current production of ultra-fine tungsten powder, two kinds of raw materials are used at the same time, hydrogen reduction tests are made under the same technique conditions, then compare the difference of particle size and uniformity of reduced tungsten powder, so as to determine which kind of raw material is more suitable for the production of ultra-fine tungsten powder, the test shows the difference of particle size and uniformity of tungsten powder after reduction in two aspects:

1.0 Effect of microstructure of tungsten oxide raw material on particle size of tungsten powder.

The results show that under the same process conditions, the tungsten powder produced by purple tungsten is often finer, and the particle size is fine and uniform, while the particle size of the tungsten powder produced by blue tungsten is larger and the uniformity is poor, which means that the particle size and uniformity of the tungsten powder are closely related to the properties of the raw materials.

2.0 Effect of reduction reaction mechanism of tungsten oxide raw material on particle size of tungsten powder.

The reduction reaction process of tungsten oxide varies with temperature and hydrogen humidity. The test shows that the reduction of purple tungsten in dry hydrogen can produce fine and uniform tungsten powder, and the reduction process of blue tungsten has two different channels at the same time, the particle size of tungsten powder reduced from one channel is coarser, but the particle size reduced from the other channel is finer, therefore it makes the particle size uniformity of tungsten powder poor.

The conclusions are as follows from the test:

1) Blue tungsten and purple tungsten can produce superfine tungsten powder under certain reduction conditions.

2) Due to its special pore structure, purple tungsten has good air permeability, which can quickly discharge water vapor from the reduction atmosphere, thus produces fine and uniform tungsten powder. And the particle size of tungsten powder is less affected by the loading capacity and hydrogen flow rate, which can show the advantages in productivity.

3) Fine and uniform tungsten powder can be gotten provided purple tungsten reduced in dry hydrogen not goes through the intermediate stage. The technique conditions should be controlled during the reduction process to avoid the aggregate of tungsten dioxide.