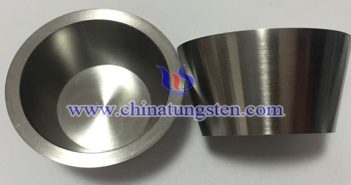

Evaporating tungsten boat is referred to as the tungsten boat that is widely applied in the vacuum evaporation coating industry. This type of tungsten boat is used at high vacuum environment so that its demand of work environment is relatively strict. The evaporating tungsten boat is different from other types of tungsten boat in: This type of tungsten boat is generally composed of a tungsten boat cover and a tungsten boat body. Generally, there are evaporating round hole on the…